Local Corn Juice Strives for Diversification through Wisdom, Smart Tech & Tenacity

Rich in insoluble fiber and zeaxanthin, corn is essential for regulating blood sugar levels and reducing the risk of macular degeneration, a chronic eye condition. Inspired by the homemade corn juice during childhood, the founder of 2 Plus 3 (HK) established the company 15 years ago to bring this nutritious beverage to the market. The second-generation owner takes reign in recent years, thriving and achieving a ninefold increase in productivity through smart manufacturing. The latest win include an OEM production deal with a major retail chain, and the addition of no-added-sugar fresh corn juice and high-protein drinks to its product range, sustaining the momentum of its “Made in Hong Kong” heritage.

Expanding Business Networks

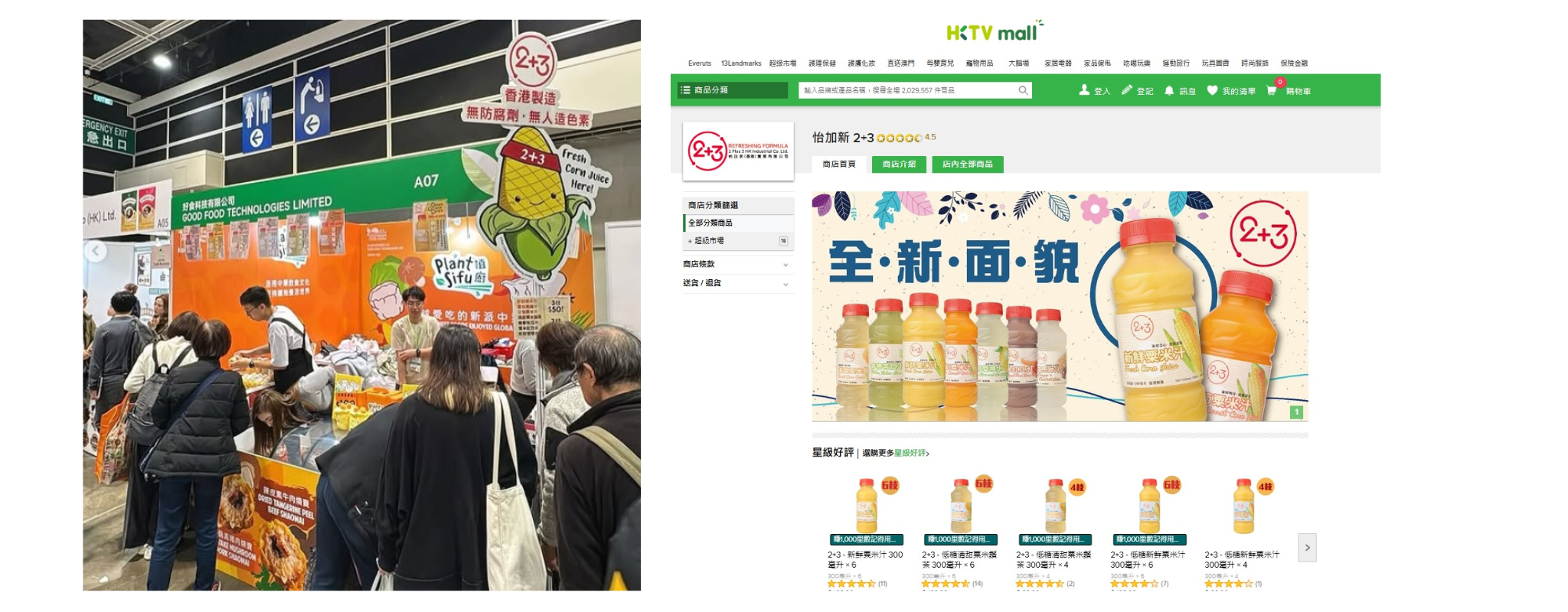

At a GS1 HK networking event earlier this year, Sam Chan, Managing Director of 2 Plus 3 (HK) Industrial Co., Ltd., connected with a representative from Big C, which led to an OEM partnership in drinks production within two months. “We see growing opportunities in partnering with retailers to develop private label products, meeting their market demands,” Sam shared. “This reflects our commitment to delivering high-quality, locally made offerings.”

Sam has actively participated in industry events and fostered connections with veterans like Hung Fook Tong, Top Soya, King Bakery, etc, sparking new ideas and business opportunities. “Currently, 2 Plus 3’s products are available in major supermarkets, convenience stores, and online platforms such as Top Fresh Bazaar and HKTVmall. Through the Hong Kong Productivity Council (HKPC), we are also exploring with university researchers to convert corn residue into secondary products, such as pet food.”

“This helps address food waste disposal, promote upcycling to give the leftovers a second life. I hope this works out soon, even if it requires investing in new machinery in the future,” Sam beamed at the idea.

Product Diversification

Specialised in fresh vegetable and fruit juices, the key customer group of 2 Plus 3 are mostly health-conscious homemakers. With the growing demand for functional foods, Sam recognises the need to develop specific beverages, such as no-added-sugar corn juice and high-protein drinks, to appeal to health-conscious consumers and gym-goers. Additionally, he is inspired to create new offerings - corn puree for restaurants and food manufacturers, as the past collaborations of corn-flavoured ice cream reaped incredibly positive feedback.

Despite challenges posed by “northbound consumption” and tightened household budget, Sam remains confident in the competitive advantage of locally produced products. “We can't compete on price alone with ‘Made-in-China’ goods, but our robust food production standards provide consumers with assurance on quality,” he emphasised. “On top of complying to the stringent local regulatory requirements, 2 Plus 3’s Hong Kong based factory is certified with ISO 22000 and HACCP food safety standards. Some high-end hotels choose us as their supplier, precisely because they value the ‘Made in Hong Kong’ label, which is a guarantee for quality.”

Smart Production: Quality and Quantity

Located in Tsuen Wan, the company’s production facility spans about 2,000 sqft. While compact, it is fully equipped, with automated machines handling cooking, grinding, bottling, sterilisation, and packaging, requiring only a few employees for onsite management. Sam recalls being taken aback by the complexity of manual production processes when he joined the company in 2018 right after graduation. The following year, he considered applying for the HKSAR Government’s “Re-industrialisation Funding Scheme” (now renamed “New Industrialisation Funding Scheme”) to introduce a smart production line. By 2023, production capacity has increased from about 1,000 bottles per day to over 8,000 bottles.

“The intelligent production line significantly enhances production capacity and improves the sterilisation process. The sterilisation parameters such as temperature, pressure, time, etc. are collected and monitored by intelligent sensors, which not only enhances the longevity of the machine, but also ensures the reliability and stability of sterilisation and improves product quality and safety. Without the use of additives and preservatives, it is expected that the shelf life can be extended effectively,” Sam explained.

The Essence of “Made in Hong Kong”

Committed to innovation and improvement, Sam is exploring collaborations with a Hong Kong virtual YouTuber for new product launch, and is contemplating to acquire higher-level food certifications for the factory.

Upon learning about GS1 HK’s “1QR”, a QR code comprising diversified information, he quickly asked his staff to adopt it out on new product packaging, so consumers can easily scan and access information about the drinks, including certifications and promotions, thus enhancing consumer confidence and interaction.

Throughout the interview, Sam’s adaptability, eagerness to learn, and proactive networking emerged as hallmarks of the “Hong Kong spirit”, which are believed to be the traits essential to driving Hong Kong’s development in a new era.